Duct Heater – Rule of Thumb for designers to calculate heater KWs

Duct heaters are the part of your HVAC that preheats the air before it is being distributed to the rooms of your property. In most cases, duct heaters are electric. Passing an electric current through resistance (coils) creates heat. The air absorbs the heat by passing through the coils and is then blown into your rooms through the ductwork. Depending on how they are used, electric duct heaters can be used as primary, supplementary, or space heating applications.

In recent years, duct heaters have emerged as an essential part of HVAC and are used for a broad range of residential, commercial, and industrial uses. A heater controls the temperature and humidity by reheating and thus regulating the temperature or by using sensible heating to control humidity.

Besides standard duct heaters, there are custom, comprehensive systems that feature the most sophisticated engineering. Depending on your comfort requirements, heating systems are available for primary heating, secondary heating, auxiliary heating reheat, or multi-zone with VAV systems.

Maxell & Duct Heaters

Maxell Industries manufactures Sheet Metal Products, Switchgear Products, and Air Terminal Products. All our units are designed, manufactured, and assembled in-house, employing some of the best-in-class equipment and manufacturing systems. Our design and engineering expertise coupled with our high-end production facilities have enabled us to become one of the top players in the HVAC industry globally.

Duct heaters at Maxell is custom engineered and designed by our team of skilled experts using our selection principles and whose specifications clarify details about elements, sheet metal, control configurations, and optional accessories.

Electric Duct Heater uses

Electric duct heaters are integral to the duct system, heating the air passing through it with electricity. Electricity is converted into heat by means of a resistance heating element. Conduction or convection transfers the heat from the resulting device to the air passing through it.

Cold rooms often benefit from electric duct heaters since they are energy efficient. Depending on the temperature of the element, these devices automatically adjust heat output as needed. Heating up an area at a specific point in time can be achieved by using electric duct heaters. By doing this, space is only heated during the time needed, resulting in efficient heat transfer without wasting energy.

By preheating returned or fresh air in HVACs, electric duct heaters can complement home and office heating. Modulating controls are available on most modern electric duct heaters, which allow them to operate at a very low airflow without sacrificing performance. Through modulation control, precise heating can be achieved when needed in today’s age of demand ventilation. Thermostats with advanced capabilities will improve precision.

Maxell manufacturers UL-listed heaters, which are primarily based on UL’s own published Standards for Safety.

The following components and specifications go into the manufacture of duct heaters. Depending on the project specs and requirements, you may select optional controls.

- Sheet metal (Galvanized or Stainless steel with required thickness till 2 mm) for enclosure

- De-energizing type magnetic contractor for stage control.

- Class-II type step down control transformer

- Auto-reset thermal cut-out. (Disc Type).

- Manual cut out as additional safety feature

- Differential airflow switch.

- Terminal blocks for power and controls cable terminations.

- SS finned tubular heating elements that are capable of operating at temperatures up to 1400°F.

Benefits:

- Versatile

- Durable against corrosion and oxidation.

- Maintenance-friendly.

- Solid and long-lasting.

- Supports local power sources.

- A safety-first design.

- Heat transfer efficiency and maximum dielectric strength.

- Minimal heat loss.

- Maintained wiring cooler.

- A clean, efficient heat source.

- Easily accessible service.

- Minimal downtime.

Electric Heater Formulas

For calculating heater KWs, designers can commonly use this rule of thumb. It is recommended, however, that the real heat load calculation be done by consultants involved in the project.

Conversion

1 KW = 3413 BTU

200 feet per minute (61 meters per minute) should be the minimum air velocity.

Minimum air velocity calculation

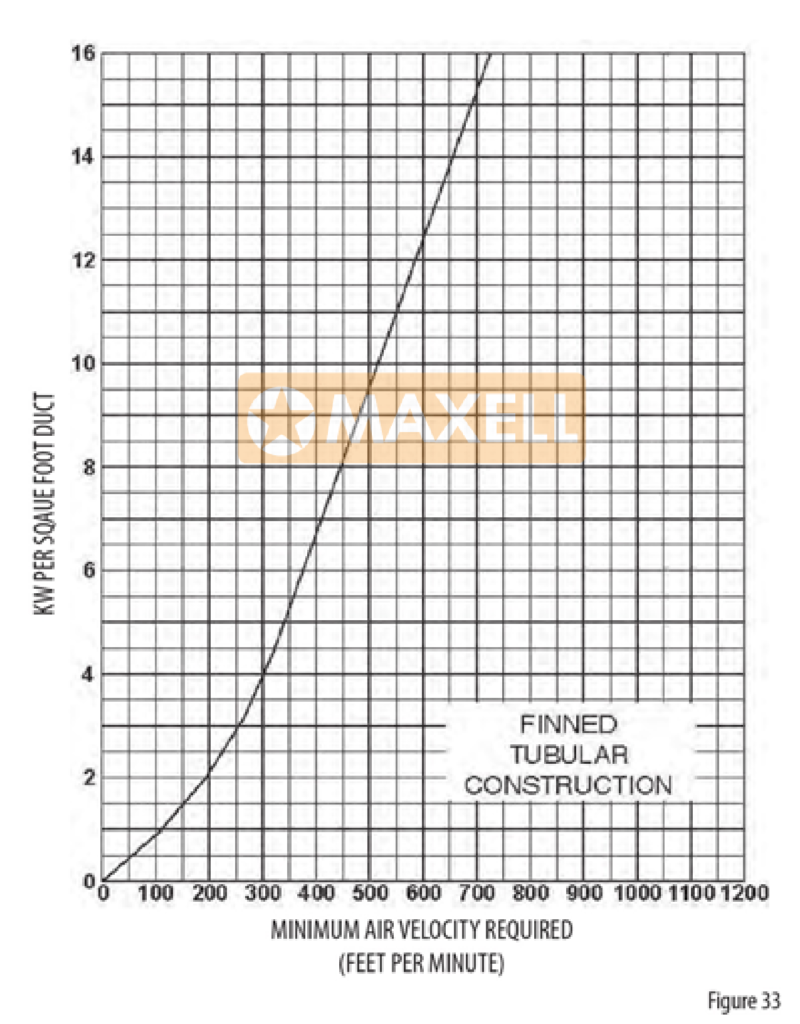

In Electric duct heaters, sufficient airflow must be provided to prevent overheating and nuisance tripping of the thermal cutouts. The minimum required velocity is determined from Figure 33 on the basis of entering air temperature and KW per square foot of cross-sectional duct area.

Example: Determine whether the minimum air velocity requirement is met for a 24 KW finned tubular heater installed in a 48” wide x 24” high duct operating with 4000 cubic feet per minute (CFM) of air at a maximum inlet temperature of 65°F:

1. Duct Area = 48” x 24”/144 = 8 sq. ft.

2. KW per square foot = 24 KW/8 sq. ft. = 3.

3. Go to Figure 33 find 3 KW per square foot on the vertical axis. Read minimum velocity required, which in this case is 280 feet per minute (FPM) Approx.

4. Heater air velocity = 4000 CFM/8 sq. ft. = 500 FPM. Since 500 FPM exceeds the minimum, this installation is safe.

Load Requirement

KW = CFM x Temp. Rise / 3160

Watts = (Volts)2 /Resistance

KW per square foot = KW / Duct area in square foot

Velocity = Airflow (CFM) / Duct area in square foot

Line Current (1 Phase)

Amps = KW x 1000 / Volts

Line Current (3 Phase)

Amps = KW x 1000 / Volts x 1.73

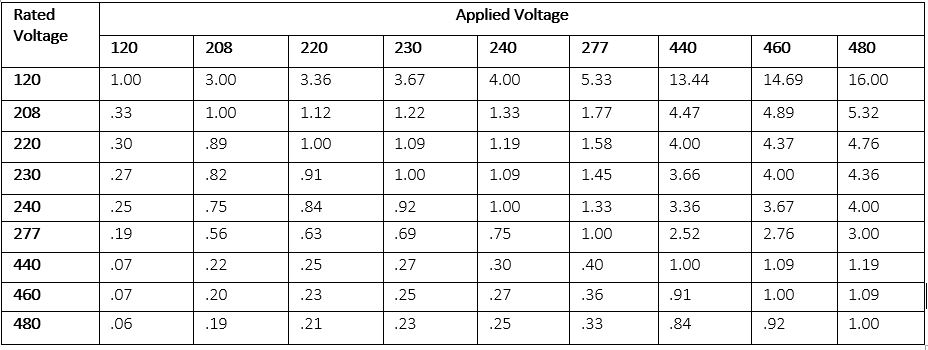

Applied vs. Rated KW Factors

| 1. Locate Heater Rated Voltage. |

| 2. Locate Actual Applied Voltage. |

| 3. Multiply Heater Rated KW by Factor Shown to Obtain Actual KW Capacity. |